UV-CIPP Tube

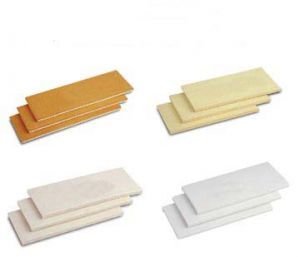

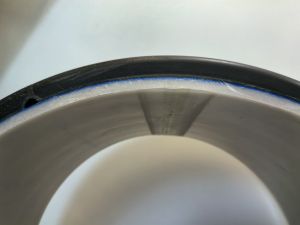

Ultraviolet light curing technology is the glass fiber into the lining hose resin, and then through special equipment to pull the lining into the original pipe, through the expansion of the lining tightly attached to the inner wall of the original pipe. The lining hose material is combined with high quality glass fiber and advanced quality benzene resin. The whole production process is automatic production equipment to ensure stable quality and short supply cycle.

| Material | Glass Fiber |

| Tube Diameter | DN150-1800 |

| Wall Thickness | 3-20 MM |

| Tensile Strength | >120 Mpa |

| Bending Strength | >390 Mpa |

| Compactness | No Leakage |

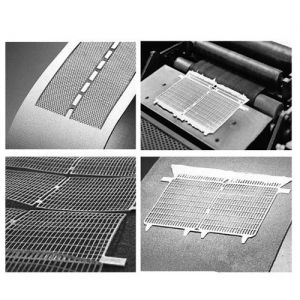

1. No need for excavation, only the inspection well to repair the pipeline, which can repair the rupture, disconnection, root intrusion and other problems.

2. The inner lining tube is made of glass fiber material, with good toughness, high strength, and good fusion with resin impregnation. The cured bending modulus is higher than 12,000 Mpa.

3. The inner wall is smooth, and the thickness of the inner lining layer is 3-20MM, which reduces the roughness of the pipe inner wall and improves the conveying capacity of the pipe.

4. Short construction period, small environmental damage, do not affect the traffic, construction safety.

5. UV-CIPP Tubes uses the pull-in installation process, after curing through ultraviolet light, the lining has high strength and corrosion resistance.

CIPP pull-in resin lining method is a non-woven felt hose with anti-seepage film. After the resin is fully soaked, it is pulled into the pipe from the inspection well to be repaired, and the hose is rounded with water pressure or pressure, and after curing, a strong and smooth new pipe is formed to achieve the purpose of repair. The loss of the cross section of the pipeline is basically negligible, but its mobility is greatly improved. The repair technology can repair PVC pipe, cast iron pipe, steel pipe and concrete and other materials of underground pipe, can be used for the repair of water supply, sewage and gas pipeline, and also can be used for chemical industry pipeline repair, especially suitable for urban traffic congestion, ground facilities.

1. Repair and transformation of urban pipe networks: Urban pipe network systems are an important part of urban infrastructure. With the development of cities, the aging and damage of pipe network systems are becoming increasingly prominent. Various pipes in urban pipe networks can be repaired and transformed quickly and effectively to improve the operating efficiency and safety of the pipe network.

2. Pipeline Rehabilitation at Wastewater Treatment Plants: Pipelines at wastewater treatment plants are susceptible to corrosion and wear, and these pipes can be rehabilitated to increase their durability and service life.

3. Repair of pipelines in chemical enterprises: The medium transported by pipelines in chemical enterprises usually has the characteristics of high temperature, high pressure, and corrosiveness. The repair work of such pipelines can be completed quickly and effectively.

4. Repair of underground pipelines: For pipelines buried underground and difficult to excavate, they can be repaired without excavation to avoid the impact of excavation on roads, buildings, etc.

5. Emergency repair: In the event of emergency situations such as leakage and rupture of pipelines, we can quickly reach the scene, carry out emergency repairs, and restore the normal operation of the pipeline.

can not be empty

The E-mail format is not correct

can not be empty

can not be empty