CIPP Dry Tube

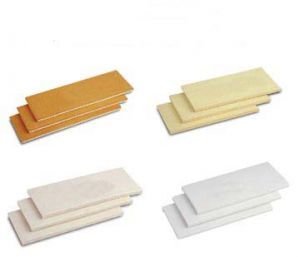

The polyester felt CIPP liner is usually made of one or more needle polyester felt layers taken together to form one tube. Fiber reinforcement can be applied and considered according to special piping. The seam in the main tube is formed by overlapping hot bonds or stitching the adjacent edges. The outermost felt layer of each low pressure dry tube is coated with an impermeable thermoplastic film to allow the vacuum assisted resin saturation tube, resin sealing, and sealing the liquid for flipping the tube and curing the resin.

| Material | Polyester Felt |

| Pipe Diameter | DN80-2000 |

| Continous Length | 1500 m |

| Thickness | 3-30 mm |

| Coating | Polyethylene |

| Technics | Machine Sewn |

1. The lymph membrane layer adopts special formula, no wrinkle, low friction coefficient, easy to flip and long distance construction, the adhesion strength of the membrane and felt is high, no peeling or foaming.

2. Full brake thermoplastic - the shower film layer sealing welding adopts automatic thermal sealing process, stable and reliable, no leakage, no cracking, peeling.

3. Wear-resistant, corrosion-resistant, service life designed as needed, up to 50 years.

4. The surface of the CIPP Dry Tube is smooth, and the friction of water flow is reduced

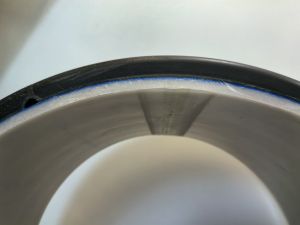

The technique uses a fiber reinforced hose or woven hose lined with impermeable film soaked with thermosetting resin, turns one end of the resin-soaked hose and holds it at the entrance of the pipe to be repaired, and then turns the inner layer of the soft liner soaked with the resin using water pressure or air pressure to the outside and bond with the inner wall of the old pipe. When the soft lining pipe reaches the end point, immediately inject hot water or steam into the tube to solidify the resin, forming a layer of hard lining with anti-corrosion and anti-seepage function that is close to the inner wall of the old pipe. The flexibility and internal pressure of the resin tube before curing allow it to fill the crack, cross the gap and bypass the bending section. After the resin is cured, the soft liner forms a new tube with the same shape as the original tube and a slightly smaller inner diameter than the original tube.

CIPP Dry Tube can be used to renovate and repair pipes with a diameter of 100 mm to 1500 mm. These pipes can be water supply pipes, drainage pipes, gas supply pipes or oil pipes and other distribution pipes with materials include cast iron, steel, concrete, plastic, etc.

can not be empty

The E-mail format is not correct

can not be empty

can not be empty

- LAST:UV-CIPP Tube

- NEXT:Pipe Lining Materials